Note that a plug or taper tap needs to be used to cut threads first and that a bottoming tap should not be used to start a thread. Bottoming taps only have 1-1.5 tapered threads and are most useful when tapping blind holes that need threads to the bottom of the hole. They are useful as a general purpose tap for ferrous and nonferrous materials. Plug taps are the most commonly used taps, having around 3-5 tapered threads. They are useful for hard and difficult-to-work materials. To Tap This Size Screw Or Bolt: Use This Drill Bit: (Closest Fractional:) Decimal Inches. Taper taps have around 8-10 tapered threads, providing a relatively gradual cutting action. RECOMMEND TAP DRILL TO USE FOR 75 DEPTH OF THREAD. Each refers to the amount of tapered threads at the start of the tap. Tap styles - There are three different kinds of hand taps: taper, plug, and bottoming.

#Shender 4 drill tap chart free

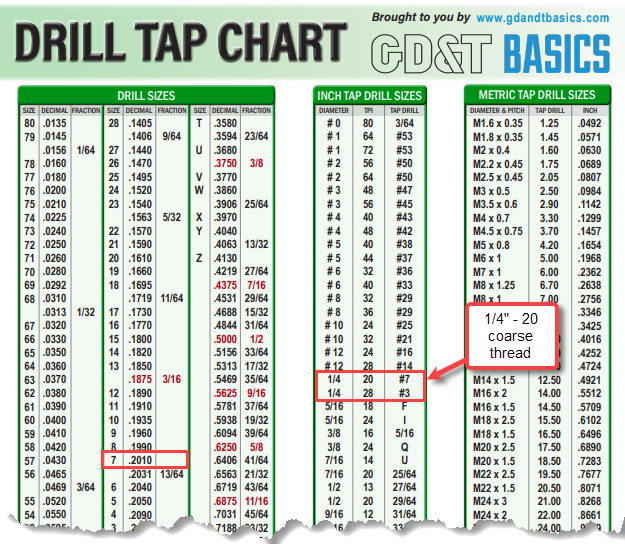

The tables below also list the standard sizes for both close and free clearance holes. The process generally includes using a spot drill or center drill to create a divot, drilling a pilot hole (see the chart below for the proper size "tap drill"), then using the tap to produce the threads. Tapping - This is the process of cutting threads on the inside of a part, and is typically done with a fluted tap. In general, this is redundant with the pitch (threads per inch), and could be omitted from an engineering drawing, but is often there to provide some redundancy in specifying the desired thread. In the context of American (non-metric) screw threads, the common standard is "Unified National", and comes in four flavors: Course (UNC), Fine (UNF), Extra Fine (UNEF), and Special (UNS). The thread or threading on the sides of the hole is needed to hold the screws or bolts in place.Screw Threads - To ensure that parts will fit together as designed, we often rely on pre-defined standards. Drill Bits come in many sizes and shapes. When it comes to drill bit sizes, there at least 153, those are the ones I can recall right now, there could be more, hence the need for a drill size chart with thread information.Ī drill bit is a cutting tool which purpose is to remove material to create a hole, it will most likely always be a cross section circular shape.

While there are common threads like the American pipe thread, the unified thread there are many unfamiliar threads. The proliferation of fittings and connectors makes correct thread identification a difficult and exhausting task even for the most experienced technician or mechanical engineers there’s always a new thread out there. A drill size chart contains drill sizes and thread data that is so large that is almost impossible for a mechanical engineer to remember it all. The best thing to do is find a tap drill clearance chart you can print, just like the one we offer in this article and print it for your lab so your team can easily access it. You might be interested in: DFM Electronics Guidelines

#Shender 4 drill tap chart pdf

You can find a drill and tap chart pdf here it’s a completely free printable tap drill chart that we hope can help you in your operations. Reading a tap drill chart is simple, taking our tap drill size chart as an example, simply scroll through the left-hand column and find the tap drill size you need, on the right you’ll find a column with the drill bit you need. For Imperial (inch) threads the tapping drill size is calculated in the same way, diameter minus pitch. 75 thread the tapping drill is 5-0.75mm = 4.25mm.

75% Thread for Aluminium, Brass, & Plasticsįor Metric threads, you can calculate the tapping drill by subtracting the pitch from the diameter of the thread.

0 kommentar(er)

0 kommentar(er)